Strain Gauges Help Engineers Ensure Strong and Safe Structures

Structural safety is a top priority in construction and civil engineering. Engineers rely on strain gauges to measure stress and strain in buildings, bridges, and other structures. These sensors detect potential weaknesses early, helping prevent failures and costly repairs. By monitoring how materials respond to forces like weight, wind, and temperature changes, engineers can design safer and more durable structures. Strain gauge data is essential for ensuring buildings and infrastructure can handle heavy loads, harsh weather, and long-term wear, improving safety and extending the lifespan of structures.

Below are five ways engineers use strain gauges for structural testing and safety.

Monitoring stress in bridges

Bridges experience constant pressure from vehicles, wind, and temperature changes. Strain gauges help measure these stresses and ensure the structure remains stable. Engineers install them on key parts of a bridge to track changes over time. If stress levels exceed safe limits, maintenance teams can take action before damage occurs.

Detecting weaknesses in buildings

Buildings must withstand forces such as earthquakes, strong winds, and heavy loads. Strain gauges help engineers identify weak points in walls, beams, and foundations. By analyzing the data, they can reinforce areas that may fail under stress. This improves building safety and ensures long-term stability.

Testing materials for durability

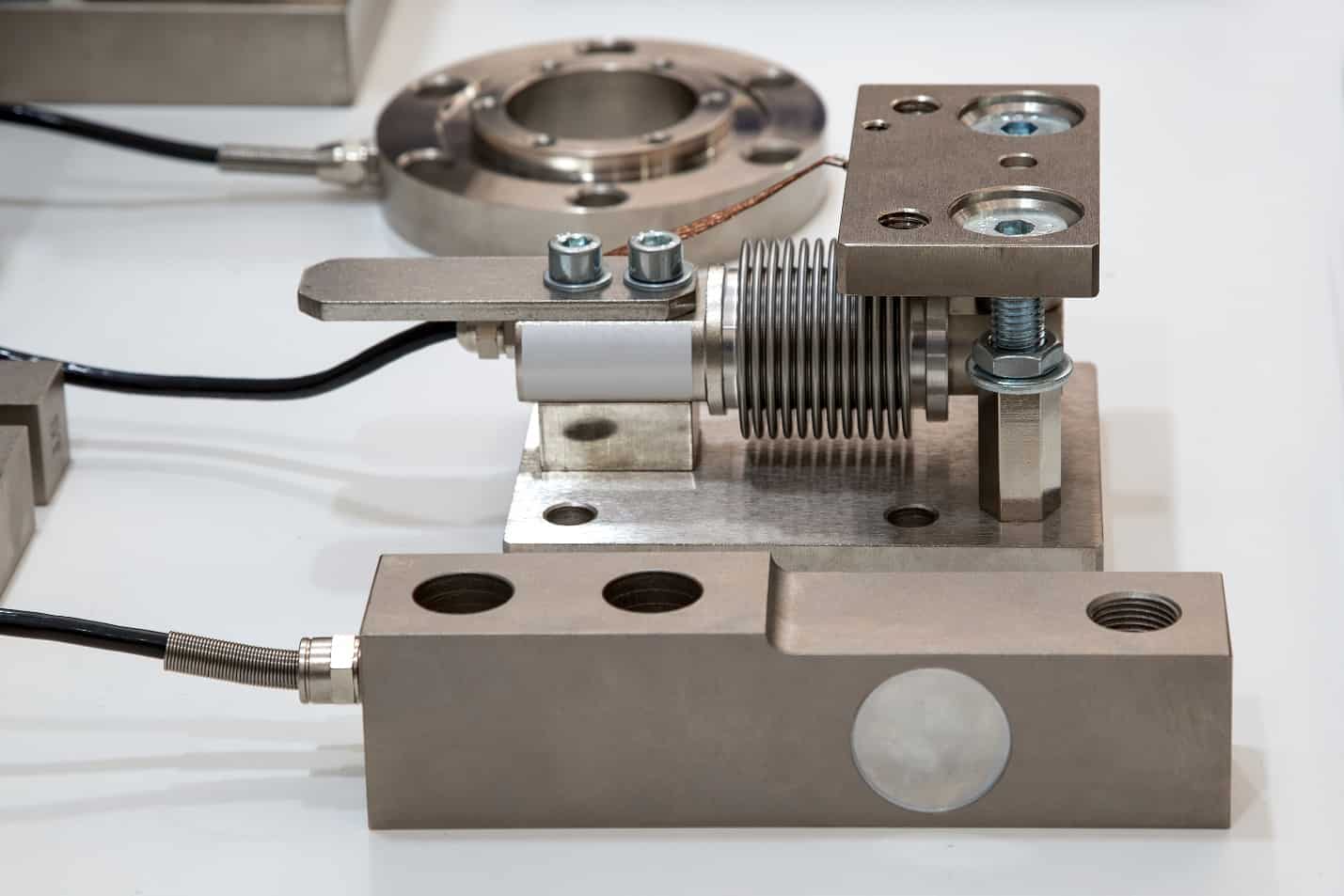

Construction materials like steel, concrete, and wood must be strong enough for different applications. Engineers use strain gauges to test how these materials react under pressure. The results help in selecting the best materials for specific projects. This ensures structures can handle real-world conditions without breaking or deforming.

Evaluating structural performance over time

Buildings and infrastructure age over time, and their materials may weaken. Strain gauges provide continuous monitoring to detect gradual changes in stress levels. Engineers use this data to schedule repairs and maintenance before problems become serious. This helps extend the life of structures and reduces repair costs.

Ensuring safety in large-scale projects

Major construction projects, such as dams, tunnels, and skyscrapers, require high safety standards. Engineers use strain gauges to test different parts of these structures under simulated conditions. This helps them design buildings that can withstand extreme forces. Strain gauge testing is essential for preventing failures in critical infrastructure.

Final words

Strain gauges are valuable tools in construction and civil engineering. They help engineers detect weaknesses, monitor stress levels, and improve safety in various structures. By using these sensors, professionals can design and maintain strong, durable, and reliable buildings, bridges, and other infrastructure.