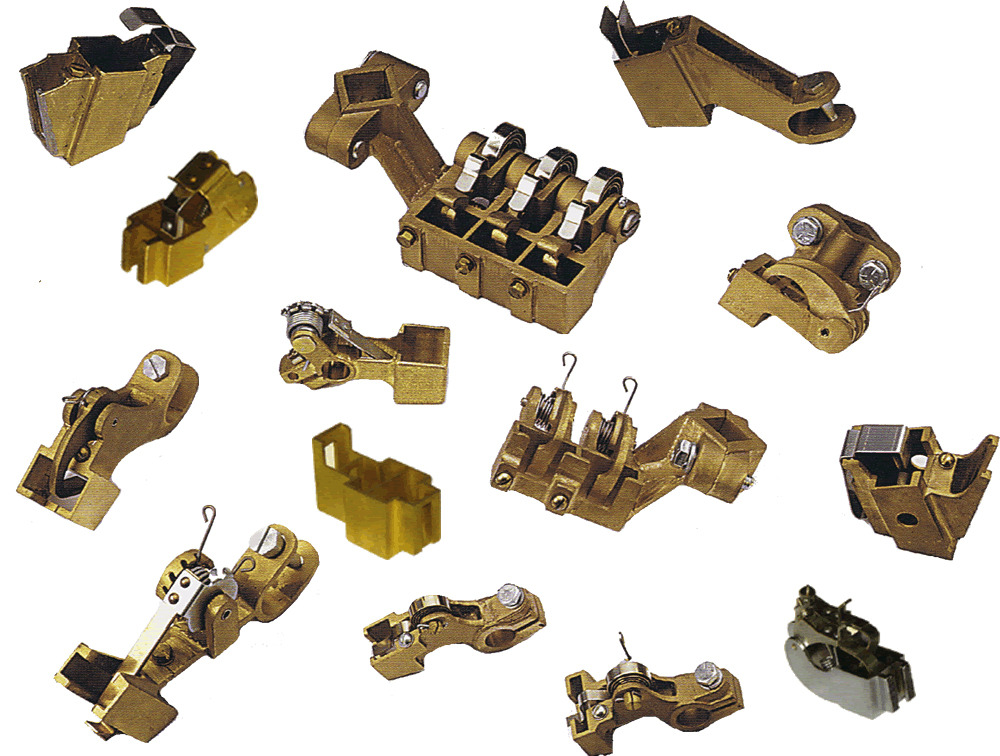

Within the sector of industry and machinery that uses motors, generators, or alternators there is one small but necessary component that makes this all happen, the carbon brush holder. The carbon brush holder performs two main functions by keeping the carbon brushes in the correct position while also ensuring consistent, reliable contact with the rotating components where current is transferred. The brush will wear and get replaced over time, the holder needs to be hard-wearing and flexible so that it fits the working environment of the machine.

As industries expand and upgrade across all sectors such as automotive, mining, and steel production, the type of carbon brush holder used can vary significantly depending on the machine and its specific function. Let us take a closer look at the different types of carbon brush holders used in various setups and understand their importance in ensuring the smooth operation of machinery.

What Is a Carbon Brush Holder?

Before we discuss the different types, it’s important to understand what a carbon brush holder actually does. In any rotating electrical equipment, carbon brushes serve to transmit current from stationary components to moving parts. The holder keeps the brushes in the correct position while applying pressure to maintain contact, and also provides isolation and support.

Whether a very large industrial motor, or small generator, the design of brush holder affects the efficiency of the brush. A faulty or incompatible holder may cause chip generation in the brush, sparking, and downtime of machines – along with expensive repairs or replacements.

1. Single Brush Holder

This is the most basic and widely used type in small machines or motors that use just one brush per terminal. These are compact and are often simple to mount – often to a brush arm directly. Although they may appear simple, the brush holder assembly does ensure that the carbon brush aligns correctly with the commutator or slip ring.

Common Uses:

- Household appliances

- Small electric tools

- Low-voltage motors

2. Multiple Brush Holder Assembly

For industrial applications with heavy load applications, e.g., mining machines, paper mills, or steel production, carbon brush holder assemblies supporting multiple brushes are more effective. The carbon brush holder assembly will hold multiple brushes in a single assembly to keep current evenly distributed.

Multiple brush holders reduce heating and wear, improving brush life and overall system efficiency.

Industries Benefiting From This Setup:

- Steel manufacturing

- Paper production

- Large-scale conveyor systems

3. Brass Carbon Brush Holder

Brass carbon brush holders are used in environments that require better heat dissipation and corrosion resistance. Brass, being a good conductor and highly durable, is ideal for holders exposed to extreme temperatures or chemical fumes.

A holder of this type is mostly customized depending on the brush size of the machine, the spring tension applied to the brush, and how it is mounted. It is not limited to a specific industry or application; they are useful wherever the conditions are harsh.

Ideal for:

- Chemical processing industries

- Marine applications

- High-speed electric motors

4. Enclosed or Insulated Brush Holders

Where contamination or moisture is a concern, enclosed brush holders are preferred. These holders are built with protective casings that shield the brushes from dust, oil, or water ingress.

Insulated holders also help maintain electrical isolation between the brush and the grounded motor body, ensuring safer operation. They come as part of a larger brush holder assembly, especially in power generation and rail applications.

Typical Use Cases:

- Wind turbines

- Locomotives

- Outdoor generators

5. Adjustable Carbon Brush Holders

Some machines require flexible brush positioning depending on wear and rotation direction. Adjustable carbon brush holders come with a mechanism to reposition the brush without dismantling the setup completely.

This type is usually used by engineers who want precise control over brush alignment to minimize sparking and arcing.

Popular In:

- CNC machines

- Specialized rotary systems

- Research equipment

Choosing the Right Carbon Brush Holder: Why It Matters

No matter the industry, selecting the proper carbon brush holder when replacing brushes is as important as selecting the right brush material. Here’s why:

- Performance: A mismatched holder can lead to irregular brush wear or misalignment.

- Safety: Using a proper holder minimizes sparking, which is especially dangerous in explosive and flammable environments.

- Longevity: The right holder helps increase the life span of both the brush and the rotating component.

- Cost-Efficiency: Longer maintenance intervals and less breakdowns ultimately save money on operational costs.

Finding reliable carbon brush holder manufacturers ensures your equipment has parts that are manufactured to very specific dimensions, not simply matching brush sizes, but also proper mounting, spring tension, insulation properties, and more.

Maintenance Tips for Carbon Brush Holders

To get the most out of your brush holder assembly, regular checks and maintenance are a must. Here are a few practical tips:

- Inspect Brush Wear: Uneven wear usually points to misalignment or incorrect spring pressure.

- Clean Regularly: Dust and debris can cause poor contact or overheating. Use a dry brush or vacuum for cleaning.

- Check for Corrosion: Especially for brass carbon brush holders, ensure there’s no greenish or black buildup, which may impact conductivity.

- Secure Mounting: Make sure holders are tightly secured and not vibrating, as this affects contact stability.

- Replace Damaged Holders: Cracked or worn-out holders can be a bigger problem than worn brushes.

Final Thoughts

From single brush holders utilized in small machines to brass carbon brush holders designed for heavy industrial systems, selecting the correct type is important for proper and reliable operation. Because of the tremendous number of variables from environment to load capacity, there is not a one-size-fits-all solution for carbon brush holders.

In many applications, especially those involving industrial brushes, the choice of holder plays a key role in how effectively the brush can perform under constant stress and movement. Industrial setups demand durability, precision, and compatibility, making it even more important to match the holder to the brush type and usage conditions.

If you are uncertain of which holder fits your application, it is best to reach out to experienced carbon brush holder manufacturers who can advise you based on your application and equipment configuration. A properly designed carbon brush holder assembly can make a large impact on machine life, operator safety, and productivity.